There’s significant discrepancy between power values measured on different dynamometers. Sometimes this difference is unintentional, and other times it’s deliberate. In this article, we explain how to determine if the power value you’re given is accurate or not.

Throughout this article, we’ll be referring to dyno testing WITH a dynamometer, as this is the only type of test bench that can be properly calibrated. Inertial dynos are impossible to calibrate correctly unless they have an associated dynamometer (I’ll explain this in a future article).

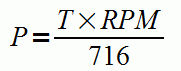

Power is derived from the combination of torque and RPM according to the power formula shown in the cover image.

Where:

T: Torque in kilogram-meters (Kgm)

RPM: engine rotational speed in revolutions per minute

P: Power in HP

As we can see, power is obtained by multiplying torque by RPM. Therefore, if we measure either of these values with an error, we’ll also measure power with an error (there’s another source of error we’ll discuss later).

RPM is measured digitally and it’s rare to have a significant error, as it generally doesn’t require calibration.

The Load Cell’s Contribution to Measurement Values

Dynamometer test benches use a load cell for measurement, which is an electronic device that converts the force being exerted by the dynamometer into an electrical signal that is read by the system. This element necessarily requires calibration, and that’s where the most significant error can occur.

The load cell calibration procedure requires hanging a weight of known value on the dynamometer’s calibration arm. The purpose of this is to generate a torque of known value just as would be produced by an operating engine.

Torque is Force x Distance, therefore the torque that should be generated by the known weight is equal to its weight in kilograms multiplied by the length of the calibration arm to the center of rotation of the shaft (it doesn’t matter where the load cell is located).

If You’re Renting Dyno Time: Bring a Weight

For practical purposes, if you’re renting a dyno, you should bring a weight of known value and hang it from the calibration arm.

On the system display, you should read ZERO when the weight is not mounted, and you should read the torque in kilogram-meters or Newton-meters or foot-pounds corresponding to that weight when the weight is hung (remember: force in kg x distance in meters). It’s important that you read the power value WITHOUT CORRECTION for climatic factors since these do not affect the calibration weight in any way.

If you suspect the RPM is measuring incorrectly, use a precise (digital) tachometer to compare the reading. Keep in mind that some analog tachometers, even Autometer ones, have errors of more than 200 RPM!

Calibration of Atmospheric Correction Factors

Another factor that can influence the power value is the atmospheric correction factor. The value of this correction will depend on the ambient temperature, humidity, and pressure. Make sure that the system you’re using for testing has these inputs, either manually or automatically. ALWAYS DEMAND THAT THE FOLLOWING DATA IS INCLUDED IN THE POWER REPORT:

- Value of Temperature, Humidity, and Pressure at the time of the test

- Standard used to make the correction (always use SAE J1349, it’s the most modern and accurate)

- Value of the correction factor applied. The value should be close to 1.0 (approximately between 0.95 and 1.05)

- If possible, have them provide both the corrected and uncorrected power.

FINALLY, I WANT TO CLARIFY THAT THIS RULE APPLIES ONLY TO MEASUREMENTS AT FIXED POINTS. THIS IMPLIES THAT THE POWER READING SHOULD BE PERFORMED AT CONSTANT RPM. AT THE TIME OF TAKING THE SAMPLE, THE TACHOMETER NEEDLE SHOULD HAVE BEEN STABILIZED FOR ABOUT 10 SECONDS.

Conclusions

Most dyno users, for reasons of convenience and practicality, perform sweep acceleration (or deceleration) tests. While this is a quick way to make a pull, it’s a method that generates errors in measurement because the engine is subjected to an INERTIAL load in addition to the dynamometer load.

Many dynos DO NOT MEASURE the inertial load, which is why the power measured in an ascending test is less than the power measured in a descending test.

The standardized power measurement is one measured point by point, with the RPM stabilized for at least 10 seconds at each RPM point.

In the next article, I’ll explain more about the effect of inertia on dyno pulls.

Accudyno currently has an inertial compensation that allows sweep tests to be performed with the same results as steady-state testing.